Bamboo is a fast-growing and renewable plant that has important environmental benefits. It grows in many different climates, captures carbon and its root system improves soil health while preventing soil erosion. Bamboo’s natural strength and flexibility have also made it a great alternative to timber and metals for buildings, scaffolding, and many other manufacturing uses.

Studies have shown that bamboo’s outer layer is actually stronger than its inner layers. Known as the epidermis, bamboo’s outer layer is smooth and dense, containing cellulose fiber and silica particles, which contribute to the plant’s functionality and durability. Silica particles in particular may strengthen and help plants like bamboo withstand environmental stresses.

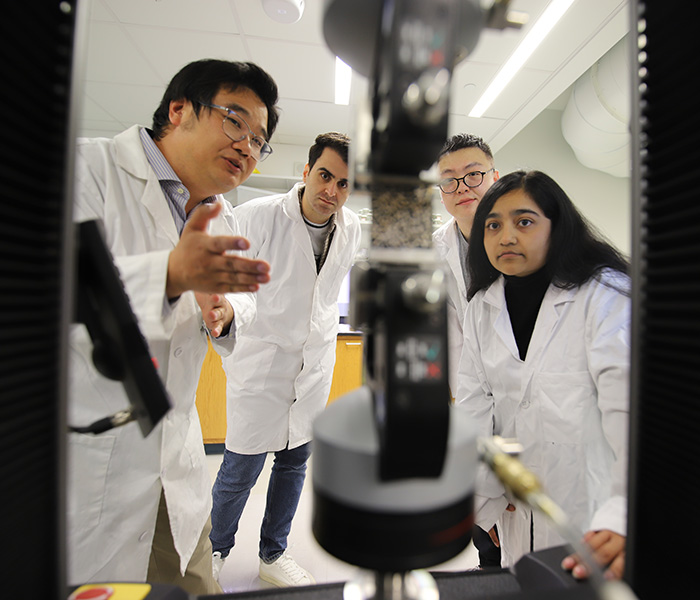

For decades, researchers have been attempting to understand how the low amount of silica particles helps strengthen the outer layer of bamboo and prevent the inner fibers from splitting. To explore this concept, Zhao Qin, assistant professor in civil and environmental engineering, combined theoretical analysis, experimental imaging, generative artificial intelligence (AI) and 3D printing to study how the arrangement of silica particles affects bamboo.

“There are individual particles embedded in the matrix material of bamboo skin,” says Qin. “We realized in the microscopic images of bamboo skin, we see when there are cracks. These cracks will be captured by the silica particles because they are harder and stiffer than the matrix. So, the crack will not propagate straight through the bamboo, but instead, it gives you the zig-zag pathway to dissipate more energy.”

When studying the structure of bamboo skin, Qin found that it’s a composite material, meaning bamboo skin is made from two or more materials with different properties. This material includes soft cellulose fibers and rigid silica particles that are arranged differently in various directions. This arrangement makes the bamboo skin tougher and more durable.

“The silica particles are very ordered in the direction that is perpendicular to the bamboo fiber bundles, with dense areas located where the bundles meet,” says Qin. “Since fiber splitting is the main way bamboo fails under different stresses, such as buckling, bending, and twisting, the silica particles at the fiber junctions help increase the material’s toughness and prevent cracks from spreading. However, their distribution along the fiber is highly disordered.”

To understand how this arrangement affects the toughness of bamboo skin, Qin input his findings into generative AI and created a model based on the structure of bamboo skin. The AI model not only looks similar to actual bamboo skin but also breaks and withstands force in the same way. This research helps us understand the mechanics of bamboo skin better, discover ways to create materials similar to bamboo, or improve the strength of bamboo materials for sustainable development.

“Understanding how the bamboo epidermis works at the microscopic level can help us connect the beginning of mechanical cracks in bamboo with larger issues like buckling and splitting when under extreme pressure,” says Qin. “This understanding is essential for making bamboo products more durable. Additionally, insights gained from the bamboo epidermis can guide the design of composites by defining particle distribution in fiber-reinforced composites, which is important for sustainable construction and manufacturing techniques.”